The molten plastic is then injected to a pre-configured mould cavity, which also cools down the material. The thermoplastic pellets are sent to a hot barrel, from which the materials are melted through a screw barrel and heater bands. This rapid process converts LDPE and HDPE pellets or granules into custom shapes and sizes defined by the mould. Once produced, the thermoplastic material may be processed for consumer or industrial use by the following methods: Injection moulding How are those two polyethylene materials processed? The process starts with polymerisation from a solution of ethylene monomers, followed by separation and drying. Most HDPE materials are produced by either slurry polymerisation or gas phase polymerisation. Its general manufacture involves the compression of ethylene gas, polymerisation using an initiator, and gas separation. LDPE is made through either a stirred autoclave or tubular reactor. Production and processing of LDPE and HDPE How is LDPE produced? High permeability to carbon dioxide and other gases

Not useful in extremely high or low temperatures Advantages and disadvantages of using LDPE vs HDPE Here's a list of the pros and cons of each of LDPE and HDPE. While both materials have their respective benefits, they also carry with them a number of disadvantages. Low, due to increased level of crystallinity Relatively increased impact strength in cold conditions Superior resistance to solvents, alcohols, acids, and alkalis low resistance to most hydrocarbons Resistant to most alcohols, acids, and alkalis low resistance to oxidising agents and selected hydrocarbons High crystallinity (>90%), which makes it tougher and more rigidĭrastic decrease in density when subjected to temperatures beyond 20☌Īble to withstand heat with temperatures more than 100☌ Low crystallinity (50-60%), and therefore more flexible Comparison of the material properties of LDPE and HDPE Meanwhile, high-density polyethylene (HDPE) is characterized by higher specific strength and heat resistance. LDPE plastic bags Properties of LDPE and HDPEĪlthough both materials come from the same ethylene monomer, the difference in chemical structure yields a wide variety of unique properties.Īs its name suggests, low-density polyethylene (LDPE) has a lower density, strength, and temperature resistance. The different applications of LDPE and HDPE

How each of them is produced and processed The advantages and disadvantages of using each polyethylene material

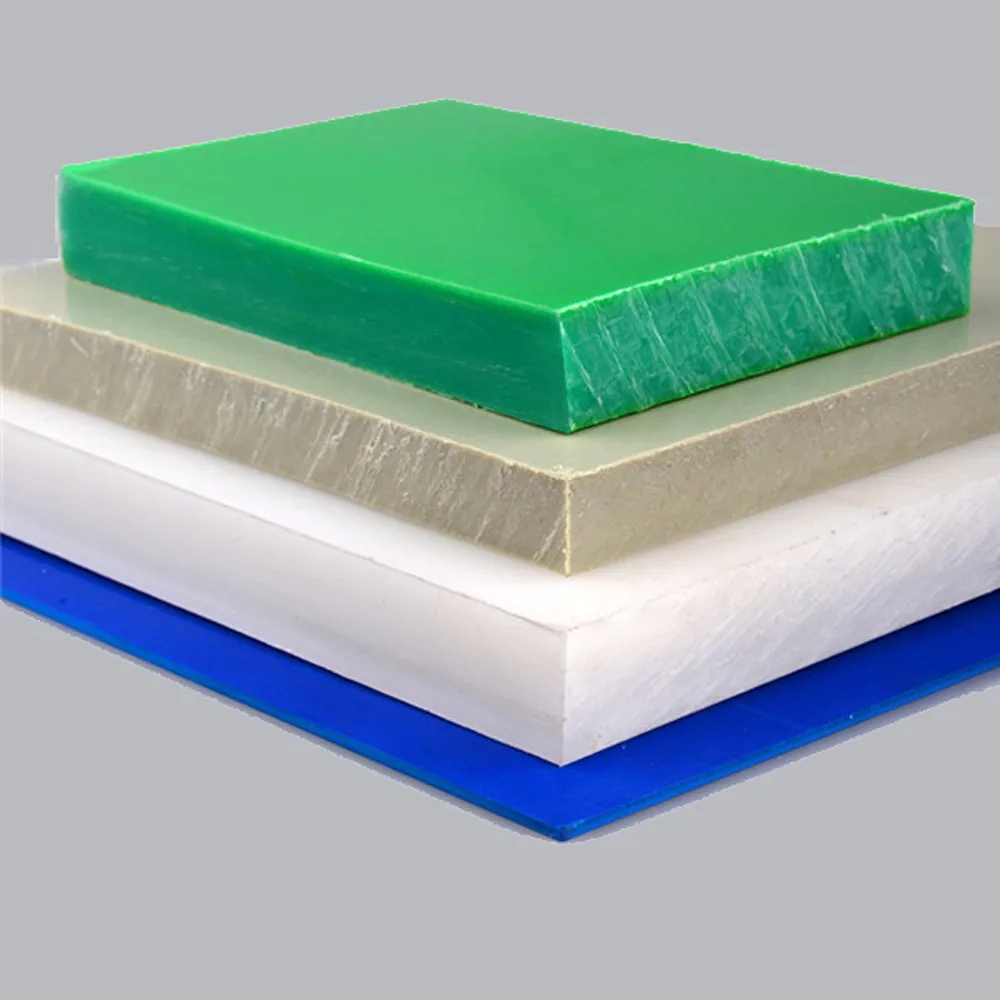

The divergence in properties between LDPE and HDPE The varying uses of LDPE and HDPE are based on this fundamental structural difference, among many other properties. That is why HDPE have a higher strength-to-density ratio than LDPE with increased tensile strength. This weakens the intermolecular forces in the polymer. Branching takes place during polymerisation, where polymer chains have secondary polymer chains attached to them by replacing an atom in the primary chain with a monomer group. One stark contrast is that LDPE has more branching than HDPE. It is also used to produce durable plastic parts such as HDPE pipes, toys and plastic chairs.Īlthough LDPE and HDPE are both thermoplastic ethylene polymers, they differ in several properties and uses. Recently, it has become very popular as a source material for 3D printing filaments, used instead of ABS material. HDPE, on the other hand, is harder and offers higher strength and better resistance to heat. LDPE is well known for being widely used in plastic bags as its low density makes it light and flexible, rendering it perfect for this kind of application. Polyethylene is the most common plastic material in the world and is known for its simple structure, the simplest of all polymers commercially available.Ĭollectively under the polyethylene class of materials, LDPE (low-density polyethylene) and HDPE (high-density polyethylene) have shaped the landscape of the packaging and manufacturing industry. LDPE and HDPE are thermoplastic materials under the family of polyolefins, which are petrochemical-based plastics that include polypropylene (PP) and polyethylene (PE).

0 kommentar(er)

0 kommentar(er)